Whatsapp: +86-18537309643 Email: cathy@unioncoding.com

| Availability: | |

|---|---|

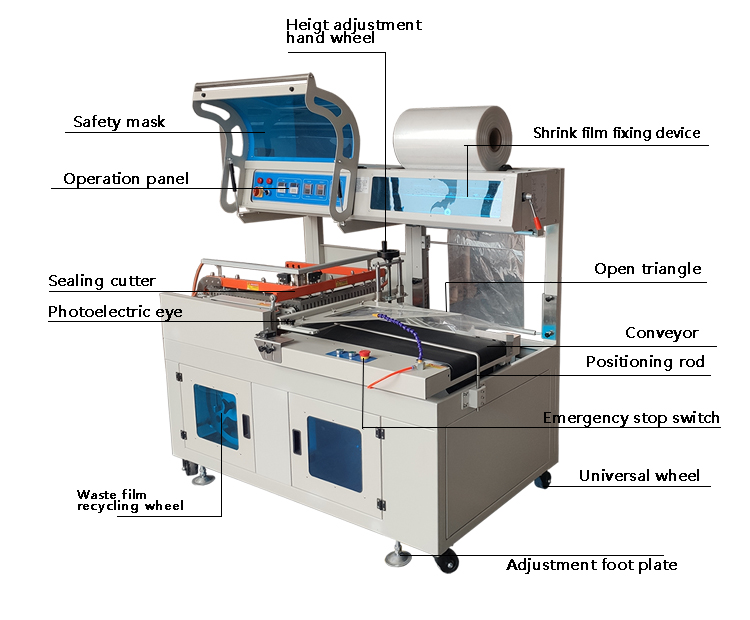

Fully Auto L-sealer, control system adopted PLC & HMI with counting & alerting features, easy maintenance. It has strong sealing line, which is thin & good look.

The sealing cutter is installed safety & alarm system to protect worker.

Features

control system adopted PLC & HMI with counting & alerting features, easy maintenance.

adopted constant heat forged bronze sealing knife, which has long life, strong & clean seal without polluted gas.

Total 2 set of vertical & horizontal sensors can be switched to work any shape of products perfectly, even thin & small size.

It is easy to change packaging size on feeding belt. The quick positioning design can save changing time without needing replacement of jig or former.

Machine is adjusted easily for size change without needing replacement of jig or former. It can also run multiple packages to help promotional purpose.

Expanded sealing size is suitable for any kinds of products with strong seal.

The auto wasting trim winding unit is driven by individual motor. It has 3-paw winding core, which can help wastage be taken out easily.

Guarding cover prevent worker from inquiry by machine operation.

It is designed by vertical sealing system.

Auto film feeding, the sensor & timer work together to control sealing length automatically.

The standing-by function can help reduce feeding seconds & increase producing capacity.

Sensitive & accurate temperature controlling system of sealing knife can be setting & changing easily.

| Voltage | 220v, 50Hz | Max wrapping size | 450*350*125mm |

| Air pressure | 0.5Mpa | Max sealing wrapping size | 560*440mm |

| Power | 1.35kw | 1.35kw | 1450*730*1360mm |

| Wrapping speed | Wrapping speed | Weight | 300kg |

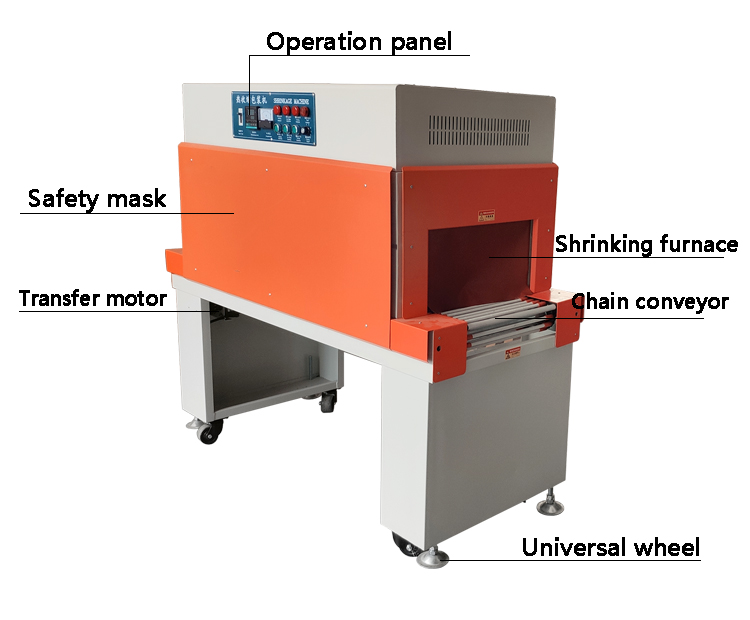

| Voltage | 380v, 50-60Hz | Conveyor belt load | 30kg |

| Power | 12kw | Shrinking furnace size | 1200*450*220mm |

| Machine dimension | 1700*720*1300mm | Weight | 160kg |

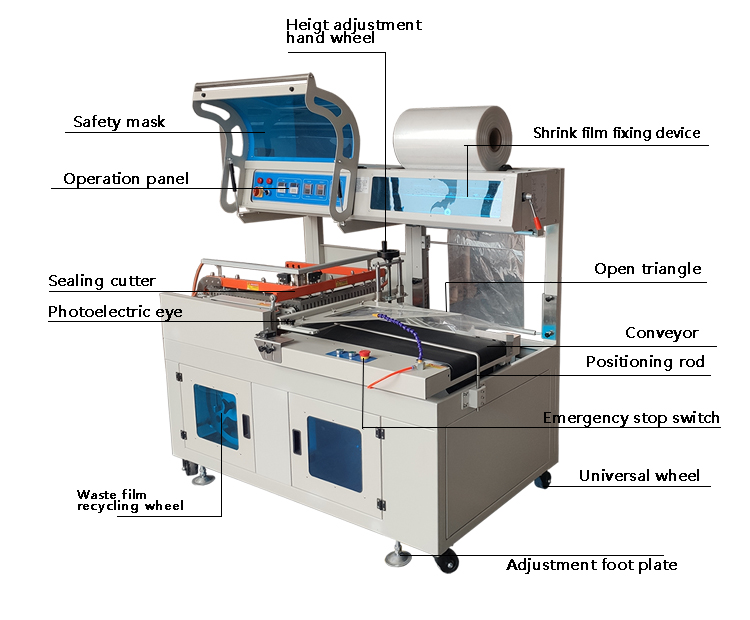

Fully Auto L-sealer, control system adopted PLC & HMI with counting & alerting features, easy maintenance. It has strong sealing line, which is thin & good look.

The sealing cutter is installed safety & alarm system to protect worker.

Features

control system adopted PLC & HMI with counting & alerting features, easy maintenance.

adopted constant heat forged bronze sealing knife, which has long life, strong & clean seal without polluted gas.

Total 2 set of vertical & horizontal sensors can be switched to work any shape of products perfectly, even thin & small size.

It is easy to change packaging size on feeding belt. The quick positioning design can save changing time without needing replacement of jig or former.

Machine is adjusted easily for size change without needing replacement of jig or former. It can also run multiple packages to help promotional purpose.

Expanded sealing size is suitable for any kinds of products with strong seal.

The auto wasting trim winding unit is driven by individual motor. It has 3-paw winding core, which can help wastage be taken out easily.

Guarding cover prevent worker from inquiry by machine operation.

It is designed by vertical sealing system.

Auto film feeding, the sensor & timer work together to control sealing length automatically.

The standing-by function can help reduce feeding seconds & increase producing capacity.

Sensitive & accurate temperature controlling system of sealing knife can be setting & changing easily.

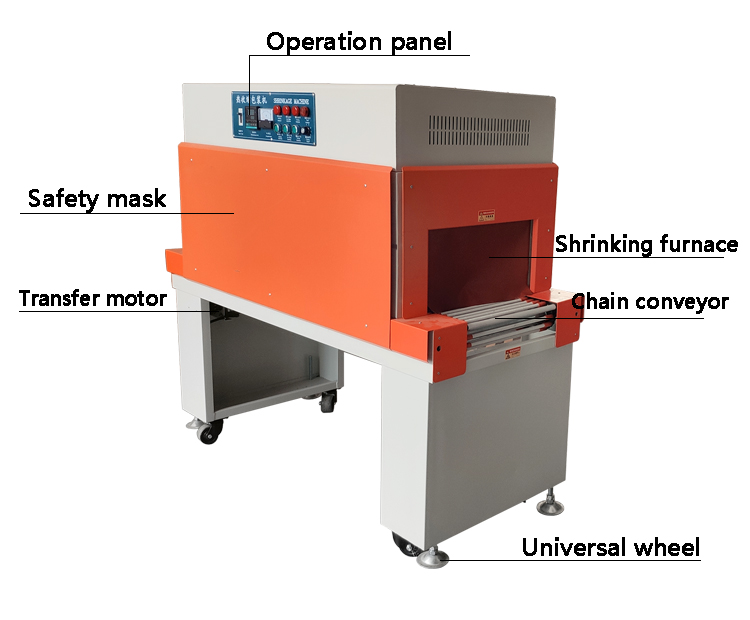

| Voltage | 220v, 50Hz | Max wrapping size | 450*350*125mm |

| Air pressure | 0.5Mpa | Max sealing wrapping size | 560*440mm |

| Power | 1.35kw | 1.35kw | 1450*730*1360mm |

| Wrapping speed | Wrapping speed | Weight | 300kg |

| Voltage | 380v, 50-60Hz | Conveyor belt load | 30kg |

| Power | 12kw | Shrinking furnace size | 1200*450*220mm |

| Machine dimension | 1700*720*1300mm | Weight | 160kg |