Whatsapp: +86-18537309643 Email: cathy@unioncoding.com

Views: 3 Author: Site Editor Publish Time: 2024-11-18 Origin: Site

In industrial and manufacturing environments, pagers are crucial tools for material handling, packaging, and automation processes. Among these, adsorbent pagers and suction pagers are widely used, each serving specific applications based on the nature of the materials being handled. While they might seem similar in their objective to move items efficiently, their underlying mechanisms, applications, and advantages differ significantly.

What Are Adsorbent Pagers?

Adsorbent pagers work by utilizing surface adhesion properties, such as static electricity, van der Waals forces, or chemical bonding. These forces create a grip between the adsorbent material and the surface of the object, enabling the pager to lift, hold, or move the object without physical clamping or suction.

This technology is often used in industries where delicate handling is critical. For instance, in electronics manufacturing, adsorbent pagers are employed to handle thin wafers or fragile circuit boards. Similarly, in the pharmaceutical and food industries, they may transport lightweight or irregularly shaped items that could be damaged by excessive pressure.

What Are Suction Pagers?

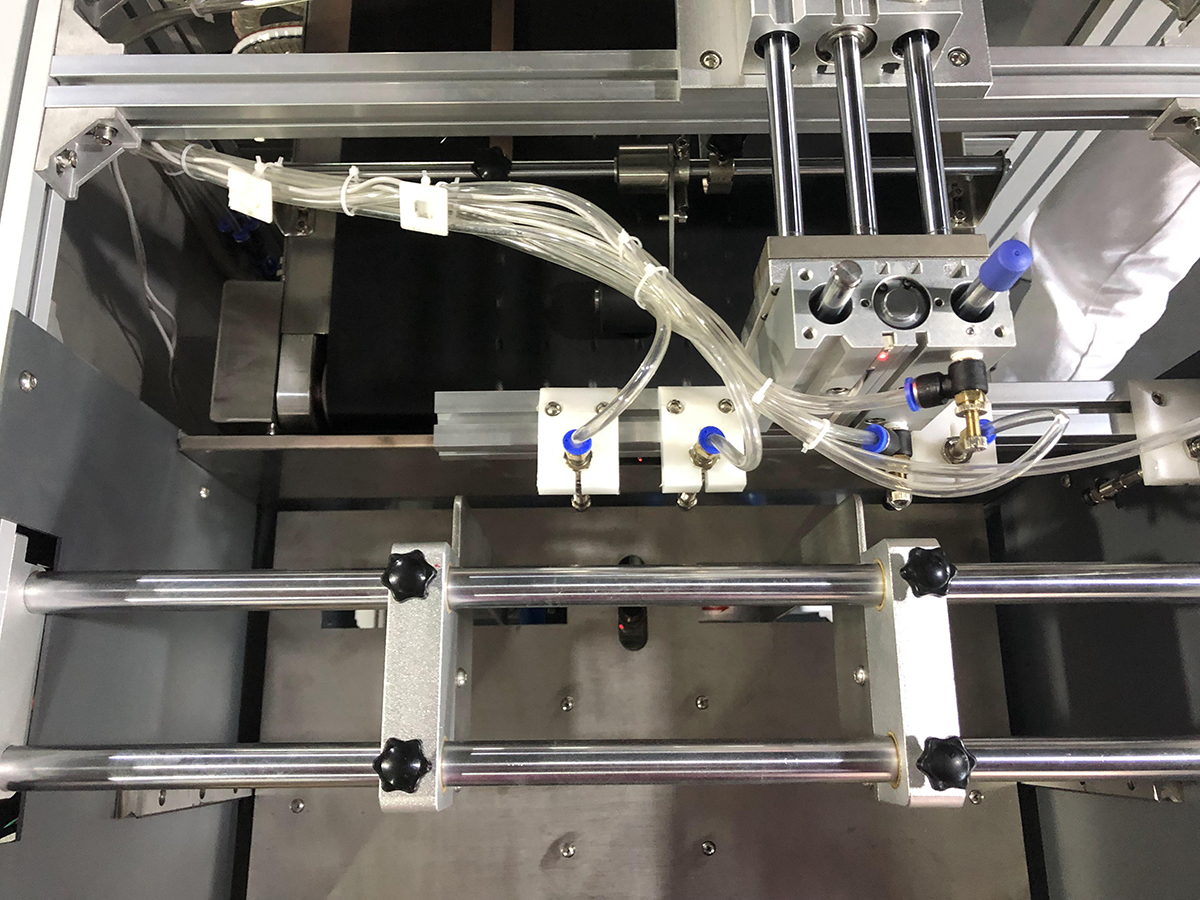

On the other hand, suction pagers rely on vacuum technology to create negative pressure that holds objects securely. These pagers typically consist of suction cups or similar components connected to a vacuum source. By reducing air pressure between the object and the suction surface, they generate a strong hold, making them suitable for a wide range of materials, especially those that are flat and non-porous.

Suction pagers are extensively used in industries that require the handling of heavier objects or materials like glass, plastic, or metal. For example, they are commonly seen in packaging lines where they lift and place items such as bottles, cartons, or sheets.

Key Differences

1. Mechanism of Operation

- Adsorbent pagers use adhesion forces, such as static electricity or molecular attraction, to grip items.

- Suction pagers rely on vacuum technology to create negative pressure for holding objects.

2. Material Suitability

- Adsorbent pagers are ideal for lightweight, delicate, or irregularly shaped items that require gentle handling.

- Suction pagers are better suited for flat, rigid, and heavier objects, especially non-porous materials like glass or plastic.

3. Applications

- Adsorbent pagers are used in industries like electronics, pharmaceuticals, and food, where precision and care are paramount.

- Suction pagers are preferred in logistics, manufacturing, and heavy-duty applications where speed and strength are critical.

4. Limitations

- Adsorbent pagers may struggle with heavy or unevenly shaped objects as their grip is less strong compared to suction.

- Suction pagers are less effective on porous or uneven surfaces where maintaining a vacuum seal is difficult.

Choosing between an adsorbent pager and a suction pager depends on the specific requirements of the application.