Whatsapp: +86-18537309643 Email: cathy@unioncoding.com

Views: 0 Author: Site Editor Publish Time: 2025-11-13 Origin: Site

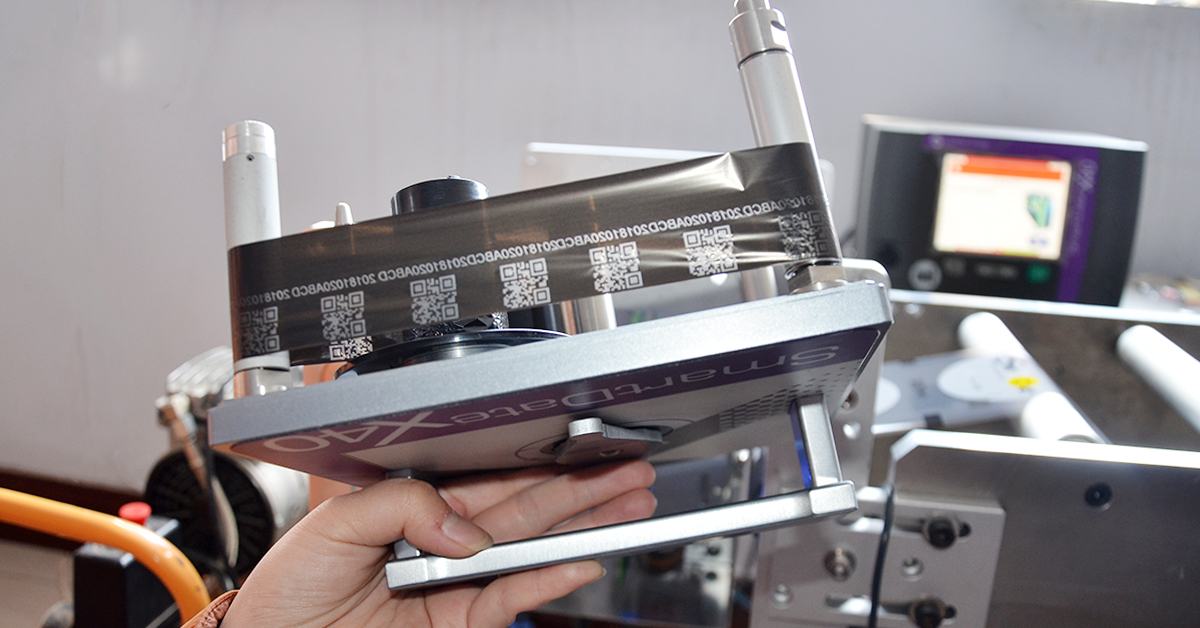

Thermal Transfer Overprinters (TTO) — such as Markem-Imaje’s SmartDate series — are widely used for printing variable data like dates, barcodes, and batch numbers on flexible packaging. While reliable, many users still encounter recurring challenges that affect production efficiency and print consistency.

1. Print Quality Problems

Blurry text, missing dots, or uneven prints usually result from dirty or worn printheads, incorrect temperature or pressure settings, or mismatched ribbons. Regular cleaning, timely printhead replacement, and using compatible ribbons with the correct settings can ensure clear, consistent results.

2. Ribbon Breaks and Waste

Frequent ribbon breaks or jams not only stop production but also waste materials. High-quality ribbons, proper tension adjustments, and quick-change cassette systems can greatly reduce downtime. Training operators on correct ribbon loading also helps prevent errors.

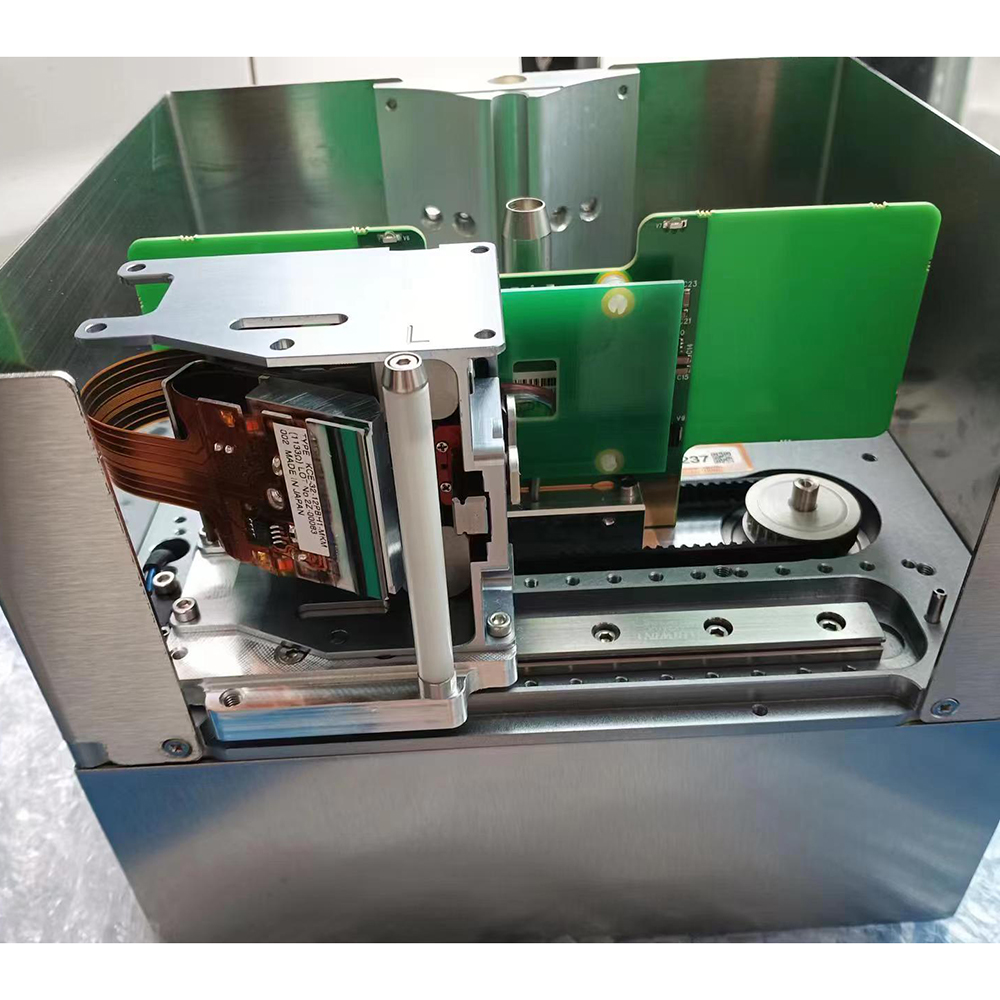

3. Unplanned Downtime and Maintenance Costs

Unexpected stoppages are a major cost driver. Modern solutions include built-in diagnostics, automatic printhead recognition, and preventive maintenance alerts. Some advanced systems even offer remote monitoring and support to minimize downtime.

4. Integration and Software Challenges

Connecting printers with existing packaging lines and databases can be complex. Using standardized communication protocols, simple user interfaces, and consistent label templates reduces setup time and human error. Comprehensive training and after-sales support also play key roles.

In Summary

By maintaining proper cleaning schedules, matching consumables, and using automation features, manufacturers can transform their Markem-Imaje TTO printersfrom a daily headache into a dependable, high-performance part of their production line.